News Center

Only by enduring trials and shouldering responsibilities can one have value.

Release Date:2017-10-21 Page View:2175

Currently, China has a large number of electric motors, which consume a lot of electricity, have aging equipment, and have low efficiency. They have fully entered a period of upgrading. Permanent magnet synchronous motors (PMSM) have the characteristics of small size, high efficiency, high power factor, large starting torque, good power indicators, and low temperature rise.

At present, China has a large number of electric motors, which consume a large amount of electricity, have aging equipment, and have low efficiency. They have fully entered a period of upgrading. Permanent magnet synchronous motors (PMSM) have the characteristics of small size, high efficiency, high power factor, large starting torque, good power indicators, and low temperature rise.

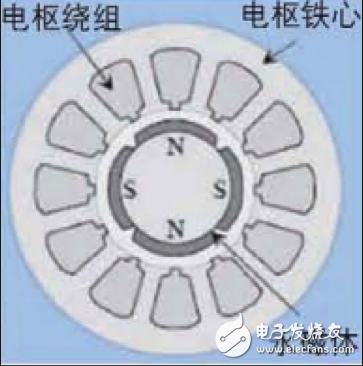

Basic principles of permanent magnet synchronous motors

A motor is an electromagnetic device that uses a magnetic field as a medium to convert mechanical and electrical energy into each other.

There are two methods to establish the necessary air gap magnetic field for electromechanical energy conversion in the motor: one is to apply current to the motor winding to generate a magnetic field, such as ordinary DC motors, synchronous motors, and asynchronous motors; Another method is to generate a magnetic field using a permanent magnet, which is a permanent magnet synchronous motor.

From the basic principle, permanent magnet synchronous motors are the same as traditional electric excitation synchronous motors. The only difference is that traditional electric excitation synchronous motors generate magnetic fields by applying current to the excitation winding, while permanent magnet synchronous motors establish magnetic fields through permanent magnets, which leads to differences in the analysis methods between the two.

Advantages of permanent magnet synchronous motors compared to AC asynchronous motors

1. Efficient and more energy-efficient:

a. Due to the fact that the magnetic field of a permanent magnet synchronous motor is generated by the permanent magnet, the excitation loss (copper loss) caused by the magnetic field generated by the excitation current is avoided;

b. The external characteristic efficiency curve of permanent magnet synchronous motor is much higher than that of asynchronous motor at light load, which is the biggest advantage of permanent magnet synchronous motor in energy conservation compared to asynchronous motor. Because it is rare for motors to operate at full power when driving loads. This is because: on the one hand, when selecting motors, users usually determine the motor power based on the extreme operating conditions of the load, and the chances of extreme operating conditions occurring are rare. At the same time, to prevent burning of the motor under abnormal operating conditions, users will further leave margin for the motor power; On the other hand, when designing a motor, designers usually leave a certain power margin on top of the power required by the user to ensure its reliability. This results in more than 90% of the actual operating motor operating below 70% of the rated power, especially when driving fan or pump loads, resulting in the motor usually operating in light load areas. For asynchronous motors, their efficiency is very low at light loads, while permanent magnet synchronous motors can still maintain high efficiency in the light load zone, which is more than 20% higher than asynchronous motors.

c. Due to the high power factor of permanent magnet synchronous motors, their motor current is smaller compared to asynchronous motors, resulting in lower stator copper loss and higher efficiency.

d. High system efficiency: The parameters of the permanent magnet motor, especially the power factor, are not affected by the number of motor poles, making it easy to design a multipole motor (such as a motor with more than 100 poles). This allows for a direct drive system directly driven by a permanent magnet synchronous motor, which eliminates the need for a gearbox and improves transmission efficiency.

2. High power factor:

Due to the fact that the power factor of a permanent magnet synchronous motor can be adjusted during design, and even the design success rate factor can be equal to 1, regardless of the number of motor poles. As the number of poles increases, the excitation characteristics of asynchronous motors inevitably lead to lower power factors. For example, for an 8-pole motor, its power factor is usually around 0.85. The more poles there are, the lower the corresponding power factor. Even the highest power factor 2-pole motor is difficult to achieve a power factor of 0.95. The high power factor of the motor has the following benefits:

a. High power factor, low motor current, reduced stator copper loss, more energy-saving;

b. The power factor is high, and the power supply for the motor, such as inverters and transformers, can have lower capacity. At the same time, other auxiliary facilities such as switches and cables can have smaller specifications, resulting in lower system costs.

c. Due to the fact that the power factor of permanent magnet synchronous motors is not limited by the number of motor poles, it is possible to design the motor with a higher number of poles, resulting in a smaller volume and lower direct material costs, as allowed by the motor's supporting system.

3. The motor structure is simple and flexible:

a. Due to the need to install guide bars, end rings, or rotor windings on the rotor of asynchronous motors, the flexibility of the asynchronous motor structure is greatly limited, while the design of the permanent magnet synchronous motor rotor structure is more flexible. For railway traction motors, the magnetic steel of the motor rotor can be directly installed on the shaft of the locomotive wheel set, thereby eliminating the need for a reduction gearbox and greatly simplifying the structure; Another example is a permanent magnet wind turbine, where the motor is made into an external rotor direct drive structure. The rotor and impeller of the motor are integrated and rotate together with the impeller, while the stator is fixed on the support tower.

b. Due to the fact that the parameters of the permanent magnet synchronous variable frequency speed control motor are not limited by the number of motor poles, it is easy to directly drive the load by the motor, eliminating the reduction gearbox with high noise and fault rate, and increasing the flexibility of mechanical transmission system design.

4. High reliability:

From the perspective of the motor itself, the reliability of permanent magnet synchronous variable frequency speed control motors is equivalent to that of asynchronous motors. However, due to the flexibility of the structure of permanent magnet synchronous motors, it is easy to directly drive the load, eliminating the need for unreliable gearboxes; Under certain load conditions, motors can even be designed inside their driving devices, such as wind power generation direct drive devices, and winch drive devices for oil drilling rigs, thereby eliminating traditional motor failure rates

High bearing: greatly improves the reliability of the transmission system.

5. Small size, high power density:

The advantages of small size and high power density of permanent magnet synchronous variable frequency speed control motors are mainly reflected in driving low speed and high torque loads. One is that the increase in the number of poles of the motor can reduce the size of the motor. Furthermore, as the efficiency of the motor increases, the corresponding losses decrease, and the temperature rise of the motor decreases. Therefore, with the same insulation level, the volume of the motor can be designed to be smaller; The flexibility of the motor structure can eliminate many ineffective parts within the motor, such as winding ends, rotor end rings, etc., resulting in a smaller volume.

6. High starting torque, low noise, and low temperature rise:

a. Permanent magnet synchronous motors can still maintain good working conditions at low frequencies, with higher output torque and lower noise during operation compared to asynchronous motors;

b. The rotor has no resistance loss and the stator winding has almost no reactive current, resulting in low temperature rise of the motor. The power of permanent magnet motors of the same volume and weight can be increased by about 30%; The volume, weight, and materials used for permanent magnet motors with the same power capacity can be reduced by 30%.

Based on the numerous advantages of permanent magnet synchronous motors mentioned above, especially in the current context of national 'energy conservation and emission reduction', their application prospects are extremely broad. With the increasingly mature and reliable control technology of permanent magnets and permanent magnet synchronous motors, their application scope can basically cover all fields of current motor applications:

Application Cases of Permanent Magnet Synchronous Variable Frequency Speed Control Motors

1. Electric vehicles

With the rapid development of the automotive industry, environmental issues have become increasingly serious. In order to solve these problems and significantly improve fuel economy, there is no doubt that electric vehicles are used. Permanent magnet synchronous motors are gradually becoming one of the mainstream motors in electric vehicle drive systems due to their advantages of high efficiency, high power factor, and high power density.

2. The field of rail transit

In 2007, Alstom developed the new generation permanent magnet traction motor system for the high-speed AGV train - V150, setting a new world record for train speed of 574.8km/h.

3. Elevator field

Permanent magnet synchronous motors generate smaller harmonic noise, which can be applied in elevator systems to bring better comfort;

4. Medical machinery field

The traditional high-speed rotating commutator motor not only has a high failure rate, but also has a short lifespan, high noise, and cannot be disinfected. The use of electronic commutation brushless DC permanent magnet motors can greatly improve work reliability, reduce noise, and extend lifespan, which is the key to developing a new generation of medical devices.

5. Home appliance industry

Due to the extremely high efficiency of permanent magnet motors during low operation, they can effectively reduce the loss of frequent starts and are one of the best technical ways to achieve energy-saving in household appliances.

6. Ship electric propulsion field

Propulsion motors are an important component of the ship's integrated power system. Permanent magnet synchronous propulsion motors have the advantages of small size, light weight, high efficiency, low noise, easy to achieve centralized remote control, high reliability, and good maintainability, making them an ideal choice for ship propulsion motors.

7. Extruder field

The screw drive motor is an important component of the extruder power system. Permanent magnet synchronous motors have the advantages of small size, light weight, high efficiency, low noise, high reliability, and good maintainability, making them an ideal choice for the extruder drive motor.

Permanent magnet synchronous motors are the foundation of numerous high-tech and high-tech industries. Combined with power electronics technology and microelectronic control technology, they can produce many new and high-performance mechatronics integrated products and equipment, representing the direction of motor development in the 21st century.