Technical advantages

Bote Motor has professional design teams, manufacturing teams and quality teams.

Bote Motor has professional design teams, manufacturing teams and quality teams.

The company has an annual production capacity of 9 million units, and the automation rate of the production line has reached 67%. The stator production process is 100% error proof implemented, the electrical performance of the finished product is 100% tested, and the data is 100% traceable. 100% visual inspection of rotor products offline, and 100% traceability of upper computer process data. At the same time, the company provides support for manufacturing activities through a comprehensive material control system.

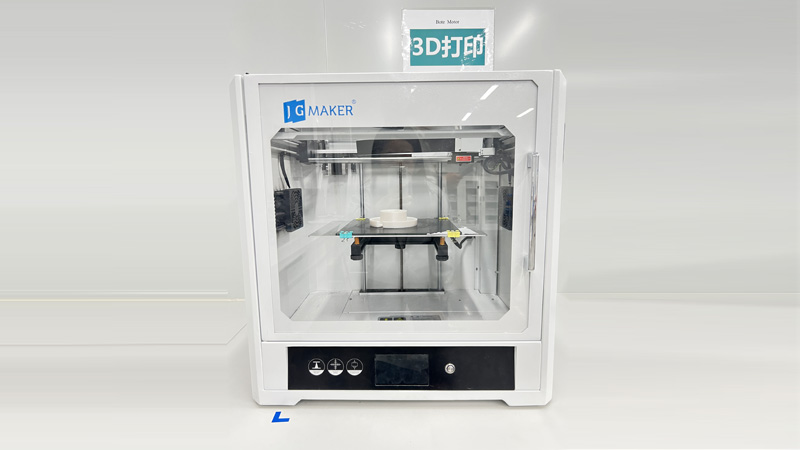

The company takes independent research and development as the leading role, and through technical cooperation with Xi'an Jiaotong University, Shanghai Dianji University and other colleges and universities, it has continuously promoted technological innovation from materials to products, from process to equipment.

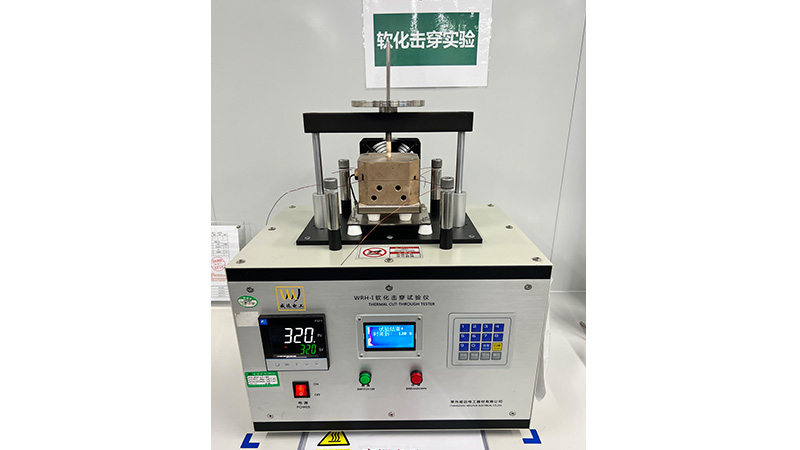

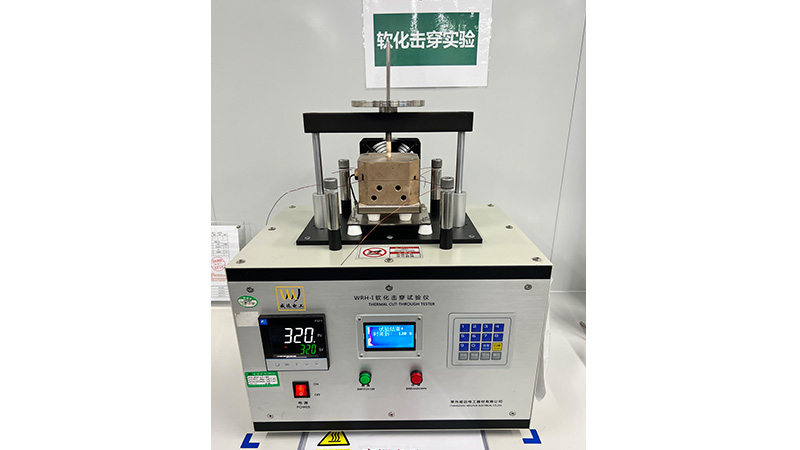

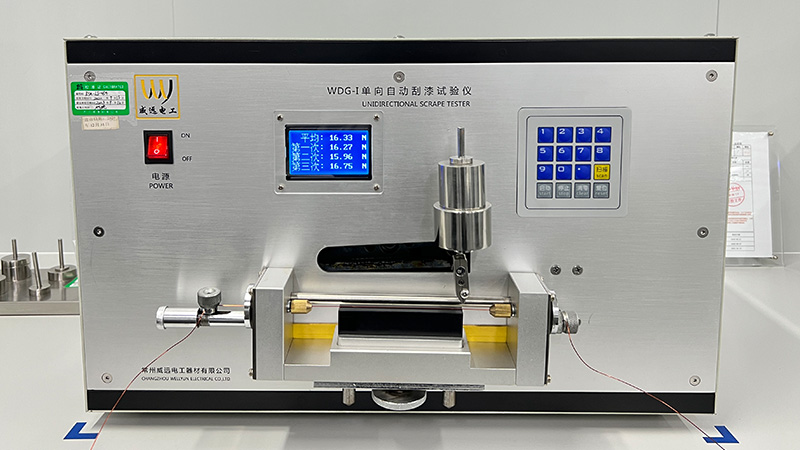

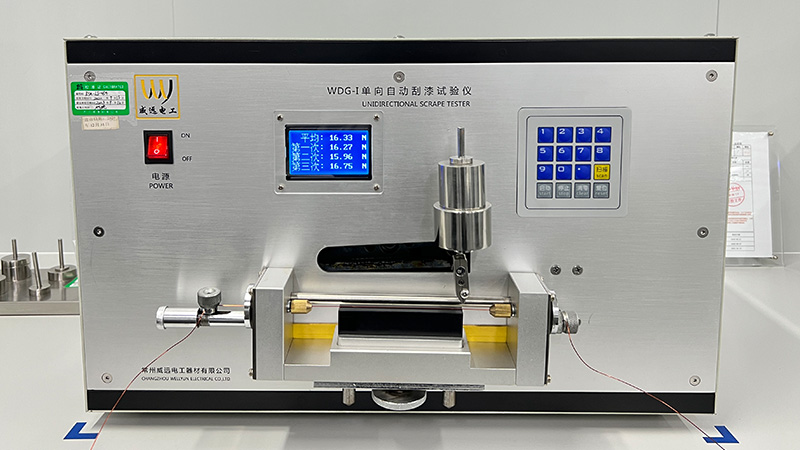

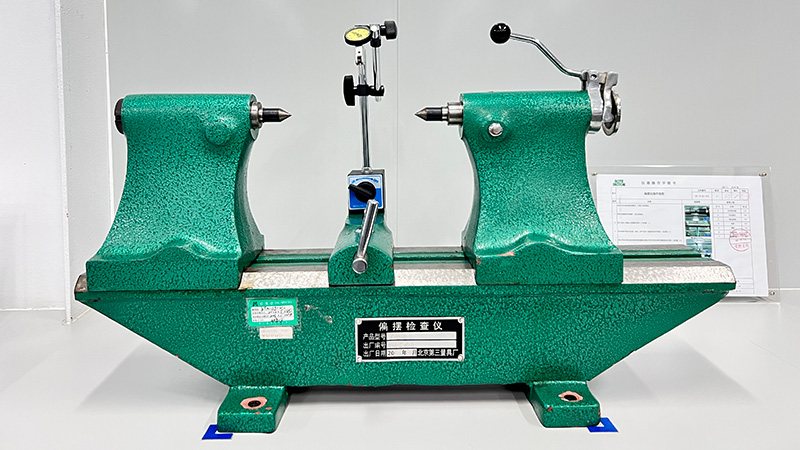

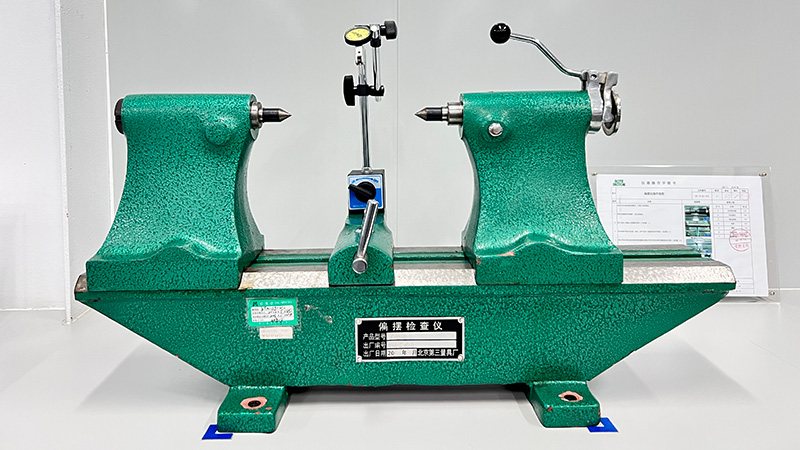

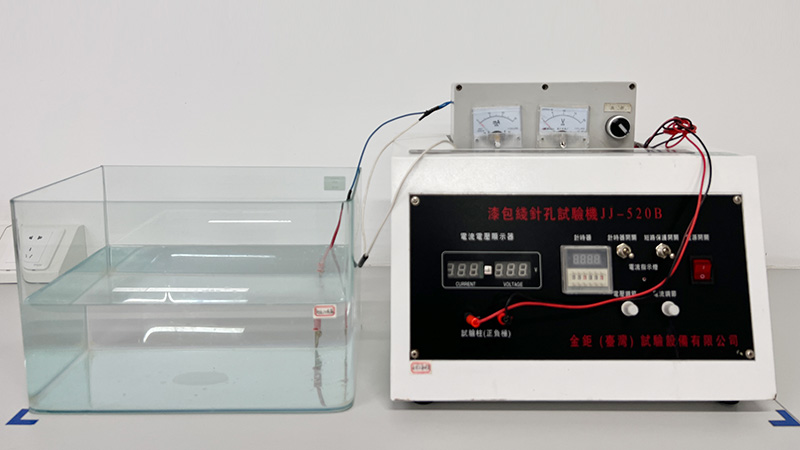

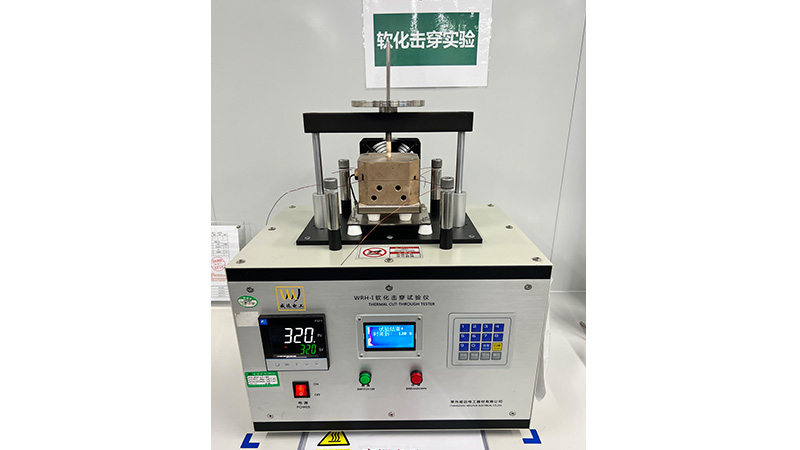

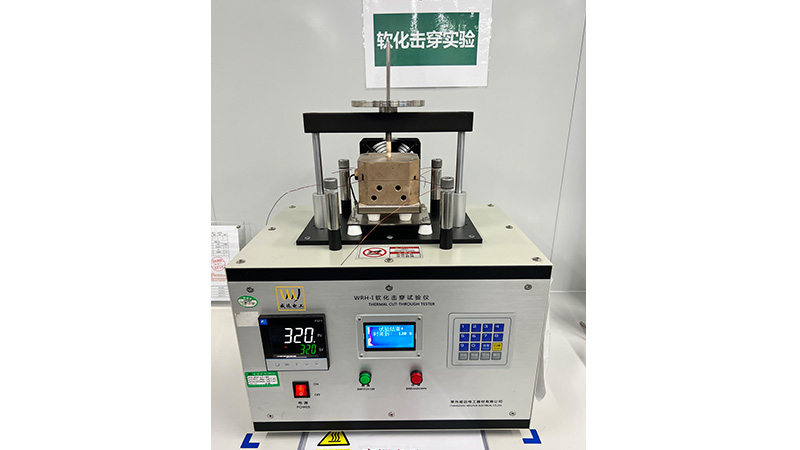

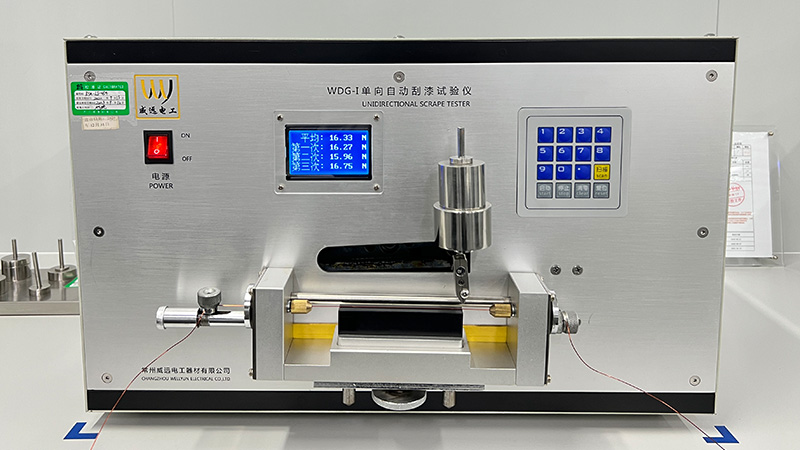

The company has established strict quality control requirements, strictly complying with regulatory requirements such as environmental safety, occupational health, harmful substances, and product quality. At the same time, internal quality management requirements have been established in accordance with the IATF16949 automotive industry global quality management system standard to ensure product quality control and traceability.

Address: No. 8, Fuhang Road,

Intelligent Manufacturing Industrial Park,

Wangting Town, Xiangcheng District, Suzhou City

Tel:0086-0512-68071530

Fax:0086-0512-68079530

Copyright © 2023 Suzhou Bote Motor Co.,LTD. All Rights Reserved.